Processing of Post-Commercial Films | LLDPE & LDPE

When recycling post-consumer films, one of the biggest challenges lies in washing and drying. Labels and glue need to be removed completely, and since the LLDPE-share is relatively high, the drying process requires additional attention and know-how. Only when all of these are addressed the right way films can be given a second life.

LLDPE & LDPE Films | Post-Commercial

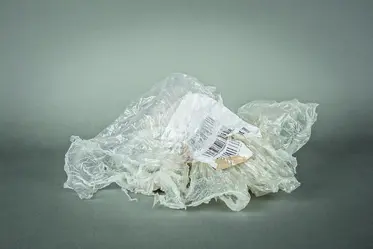

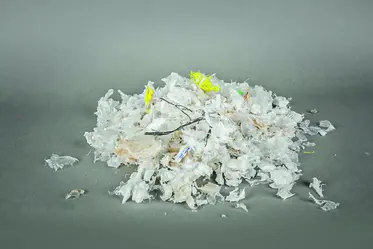

In contrast to post-consumer film, post-commercial film has a relatively low contamination level. Instead of strong odours and grease, the challenge here is to remove labels and glue. In addition, Post-consumer films contain a relatively high proportion of stretch (LLDPE), are relatively thin and have a low bulk density.

The Recycling Solution

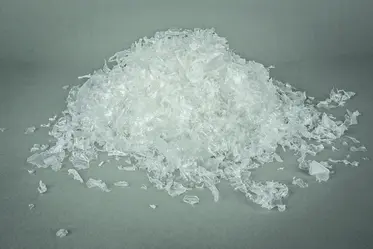

As a rule, the aim of reprocessing post-consumer films is to produce new film packaging from the recyclate. Labels and adhesives must therefore be thoroughly removed, especially for the downstream extrusion process - this usually requires a high friction and, optionally, a hot wash. When planning the drying processes, the high proportion of stretch film in particular must be taken into consideration.

"Our New 'Plastics Recycling' Business Unit Was Perfectly Supported by the Lindner Project Engineers from Start to Finish."

Oriol Llorens

Managing Director of Llorens | GMR, Barcelona

LLDPE & LDPE Films

Post-commercial film refers in general to transparent plastic films with a high stretch content, which are recovered from supermarkets and other businesses. These soft films are often contaminated with organic matter and paper labels, which must be removed and separated in a complex procedure. Drying thin stretch wrap poses a special challenge and is handled efficiently by a centrifuge from LINDNER’s Loop Dryer series. The goal is to produce a granulate for subsequent extrusion that is as transparent as possible and free of contaminants, with the same market quality as new material.