Processing of Post-Consumer & Post-Commercial Rigid Plastics | PP

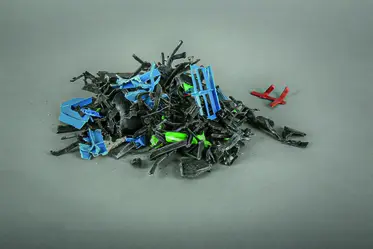

PP waste is generated as mono or mixed fractions while sorting commercial, domestic or bulky waste. The robust shredder, which is resistant to non-shreddables, reliably shreds these materials into sortable flakes. These are then mostly separated by colour, and subsequently cleaned to obtain a homogeneous source material for new, high-quality goods.

Rigid Plastics | PP

Recovered from the dual system or bulky waste, end-of-life materials made from PP plastics are usually thinner-walled than products made from HDPE plastics. They are also often very brittle and often contain organic residues such as those found in yoghurt cups. PP materials also have a lower bulk density than HDPE products due to the wall thickness and the film content.

Recycling Solution

Similar to HDPE, the best and most efficient recycling solution depends on the future application of the recycled material. In the case of heavily contaminated plastics, hot washing is a very effective solution. For these fractions, it is important to separate film and PP, for example using the LINDNER WASHTECH windsifter.

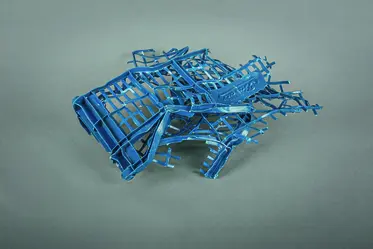

PP Packing & Boxes | PO Boxes

These are plastics such as monofractions and mixed plastics recovered from commercial waste or kerbside waste collection. The pre-shredders from LINDNER’s Micromat series are sturdy machines that are resistant to foreign objects and obstructions and reliably reduce the feed material to the defined grain size. The separation technology is of special importance to the washing process. Here the plastic with a density of > 1 g/cm³ is separated from the PO fractions using various different methods. Alongside its tried-and-tested sink-float method, LINDNER WASHTECH also offers hydrocyclone separation technology.