Processing of Post-Consumer & Post-Commercial Rigid Plastics | HDPE

When processing HDPE rigid plastics in general and HDPE rigid plastics for hazardous goods int particular, it’s especially important that the individual process steps are perfectly matched and flexible – especially if these are to be used again in the hazardous goods industry in line with the circular economy principle. In addition to the constant shredding process, the various washing steps are important. Particularly heavily contaminated containers and drums are cleaned with Lindner’s “hot-wash system”, which can be switched on and off as needed depending on the contamination and required quality.

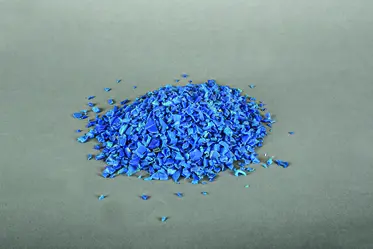

Rigid Plastics | HDPE

These plastics are mostly recovered from the dual system but also from bulky waste. Depending on their origin, they differ in material thickness and degree of contamination. Another challenge is the varying proportion of organic material.

Recycling Solution

The recycling solution for reprocessing these materials depends above all on the future area of application. If the materials are heavily soiled, oily and smelly, hot washing is usually the only option. Since these materials are usually thicker than film, mechanical drying is the primary option.

"In Lindner, We Found a Partner Who Used Their Expertise to Design Exactly What We wanted - A Facility Finely Tuned to Our Requirements. We Would Definitely Choose a Lindner Facility Again!"

Hauke Grabau

AST Kunststoffverarbeitung GmbH

HDPE Bottles and Canisters

In modern recycling systems, HDPE-bottles, HDPE-canisters and others are pre-sorted, compacted and usually handled as baled material. The purity of these pre-sorted waste fractions varies significantly from one country or region to another. The washing system can be streamlined to accommodate the intended application of the reprocessed plastic. For example, by implementing LINDNER’s Hot-Wash-System, the output material is of such high quality that it can replace primary plastic – the prerequisite for a true circular economy.